Scope of applications

Ductile cast iron piles are prefabricated driven piles of small diameter: compact shape with low displacement and minimum ground disturbance. They combine a lot of benefits that enable them to solve many problems advantageously from both economic and technical points of view. Their specific methods of installation (i.e. the simultaneous drive and grout technique) and the resulting lightweight equipment make them as appreciated for large construction projects as for small and medium-scale piling jobs.

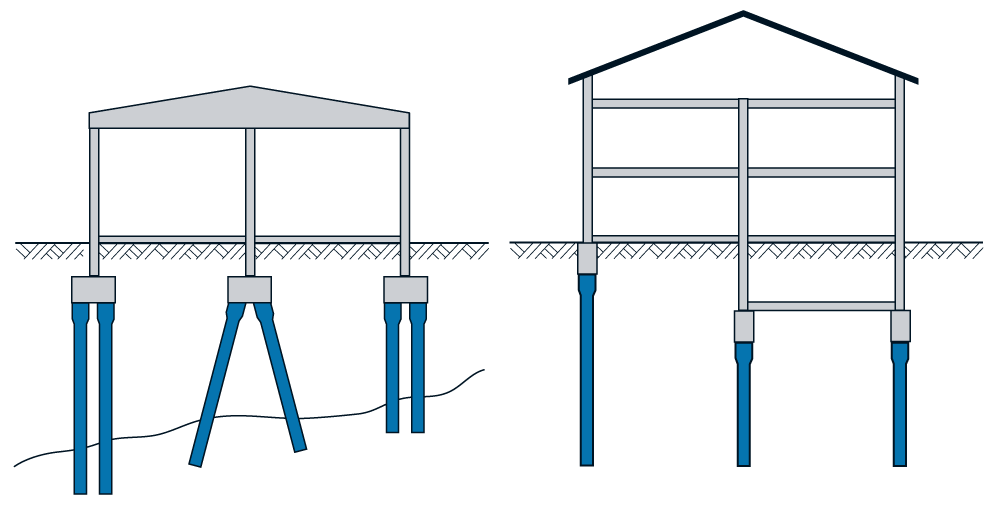

Residential and industrial buildings

Ductile cast iron piles are especially appropriate as compression piles. Thanks to the installation by displacement and to the simultaneous drive and grout technique, shaft-grouted ductile iron piles are suitable for use as combination of friction and end-bearing piles. When the geotechnical conditions allow, the closed-ended driven piles are the best compression piles. The wide range of applications includes any real estate project as well as industrial buildings. The reduced space taken by the pile caps brings significant savings when the costs for removal/disposal of excavation material and for concrete volumes are globally addressed.

Civil engineering works

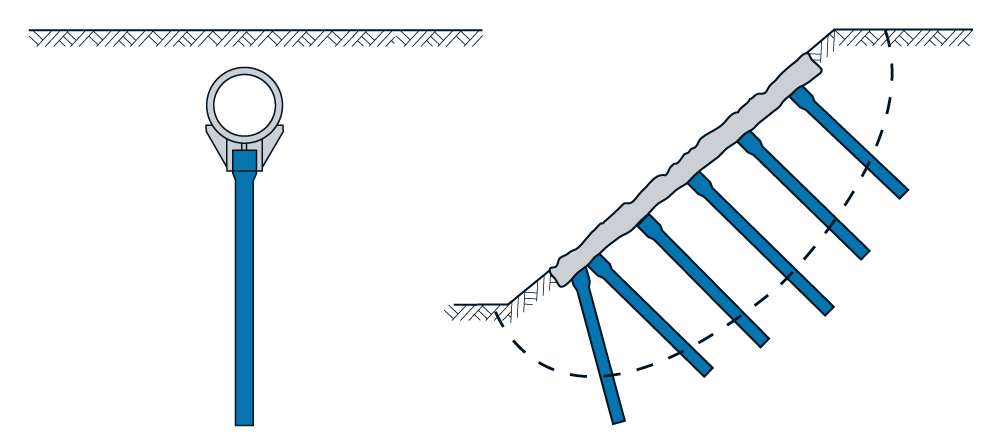

Thanks to the significant inertia of the continuous metallic tube and the easy installation of raked piles (inclination possible up to a 45 degree angle), ductile cast iron piles can support horizontal loads and high bending moments. They are particularly indicated for use in civil engineering works of appropriate dimensions (deep foundations of bridge piers and abutments for road and rail infrastructures) and in projects located in seismic zones.

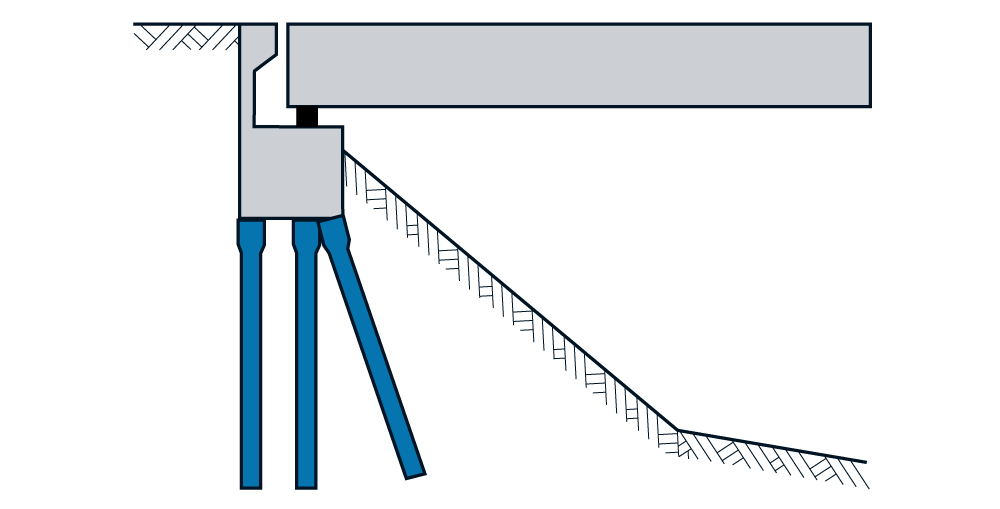

Underpinning, retaining walls

Ductile cast iron piles allow work under a limited height of 7.5 m or even 5.0 m and accessibility up to 2.5 m in width. Used in low headroom conditions, they offer impressive suitability for extension projects, rehabilitation of warehouses or strengthening of old foundations. The absence of excavated material and the low level of vibration makes their use all the more significant when the conditions of access and workspace are difficult.

For the purpose of temporary or permanent support works, cantilever or tied retaining walls of appropriate dimensions can be installed cost-effectively and quickly by using driven ductile cast iron piles.

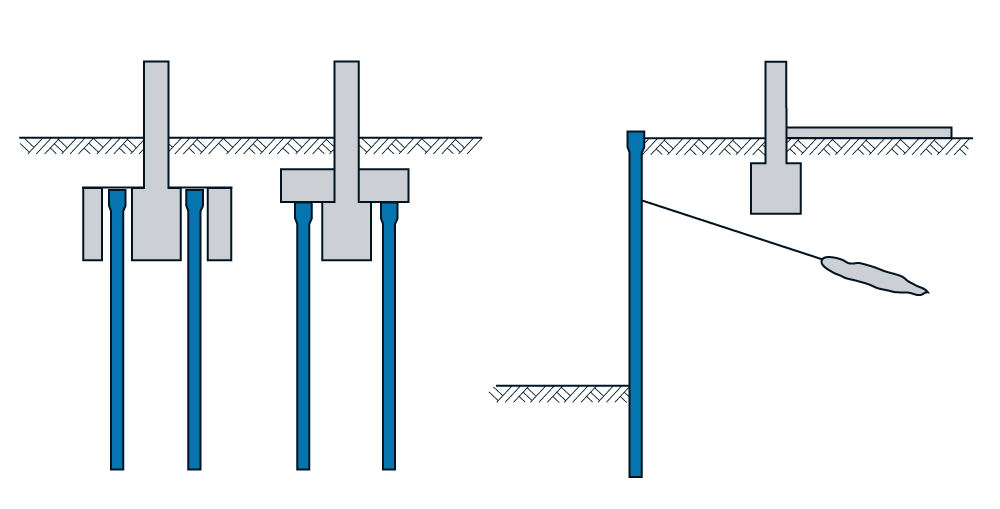

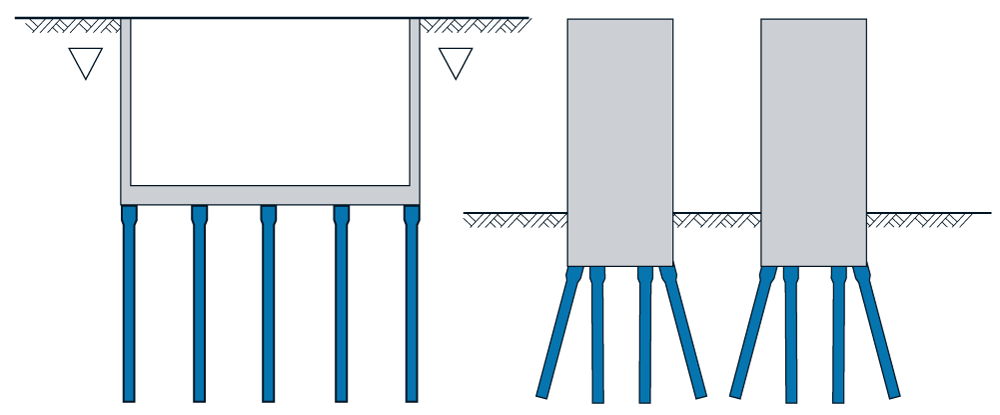

Building excavations, slender structures

Ductile cast iron piles can also be used effectively as tensile piles and give protection against hydraulic heave in deep excavations. Tensile forces are transferred to the soil by an additional reinforcement bar inserted in the tube core filled with mortar or grout (piled raft foundations, purification basins, underpasses, etc.). For foundations subjected to cyclic axial loading (tensile and compressive forces), the bilateral load capacity of ductile cast iron piles makes them extremely economic for slender structures such as silos, power line pylons, catenaries, wind turbines or antenna towers.

Pipe-laying, slope stabilization

Underground pipe-laying on ductile cast iron piles represents an economic alternative to an expensive soil replacement method. The process allows the installation of the piles at different platform levels and an accurate vertical positioning of pipes, to durably prevent settlements.

Slope stabilization, mountain roads, and preparation of ski runs: the ductile cast iron piles can be driven vertically up to nearly horizontally for protection against small-scale landslide hazard.

Acoustic protection

The construction of noise barriers for roads and railways requires compact and mobile equipment (linear job site in confined workspaces). The absence of spoils and risk of ejection allows you to secure the operational traffic lanes. The storage, working and handling areas are reduced to the minimum in order to limit the constraints on traffic.

Energy piles

The excellent thermal conductivity of ductile cast iron and the easy insertion of geothermal closed-loops inside the driven prefabricated tubes allow a double use of the piles. They can be designed as structural elements to transfer the foundation loads to deeper soil strata and as geothermal heat exchangers (heating and cooling for buildings).